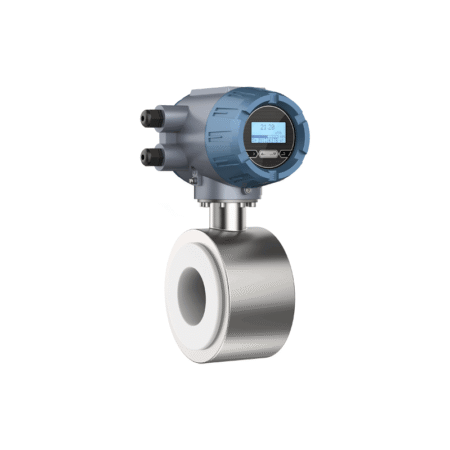

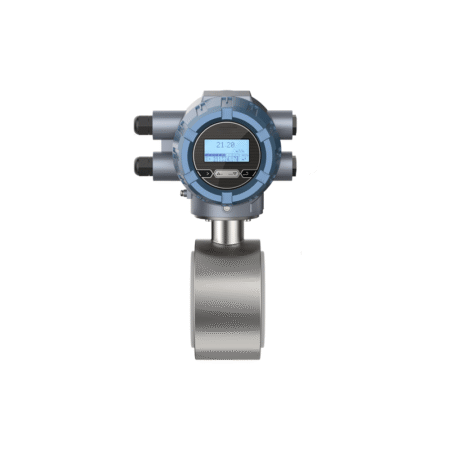

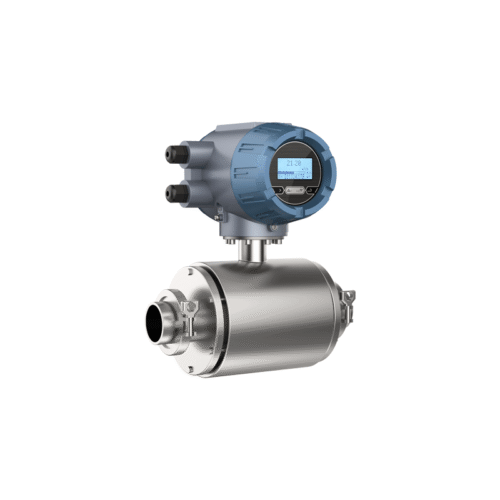

The wafer-style magnetic flow meter is also designed and manufactured according to Faraday’s Law of Electromagnetic Induction, and its composition and function are the same as the flange-type electromagnetic flowmeter. The difference is that the sensor adopts a non-blue design, compact structure, and light weight. The housing is made of all stainless steel. The shorter measuring tube is conducive to removing dirt on the tube wall and is easy to install and clean.

The wafer-style magnetic flow meter is also designed and manufactured according to Faraday’s Law of Electromagnetic Induction, and its composition and function are the same as the flange-type electromagnetic flowmeter. The difference is that the sensor adopts a non-blue design, compact structure, and light weight. The housing is made of all stainless steel. The shorter measuring tube is conducive to removing dirt on the tube wall and is easy to install and clean.

Principle

According to Faraday’s principle of electromagnetic induction, a pair of detection electrodes is installed on the tube wall perpendicular to the axis of the measuring tube and the magnetic field lines. When the conductive liquid moves along the axis of the measuring tube, it cuts the magnetic field lines and generates an induced potential. This induced potential is detected by the two detection electrodes, and the value is proportional to the flow rate. Its value is

E=KBVD

In the formula:

E-induced potential;

K-Coefficient related to magnetic field distribution and axial length;

B-Magnetic induction intensity;

V-average flow velocity of conductive liquid;

D-electrode spacing;(Measuring the inner diameter of the tube).

The sensor uses the induced potential E as a flow signal, which is transmitted to the converter. After amplification, transformation, filtering, and a series of digital processing, the instantaneous and cumulative flow rates are displayed on a back-lit dot matrix LCD. The converter has 4-20mA output, alarm output, and frequency output, and is equipped with communication interfaces such as RS-485, and supports HART and MODBUS protocols.

The main advantages of the wafer electromagnetic flow meter:

1. Lightweight and Compact Size

Because it eliminates the need for a large-diameter flange, its weight and size are significantly reduced compared to flange-connected systems, making installation and handling easier and more cost-effective.

2. Easy Installation and Maintenance

This is its most prominent advantage. To dismantle, clean, or replace the flowmeter, simply loosen the clamping bolts and remove the entire flowmeter from the pipeline without moving the pipeline or disassembling any flange connections. This is crucial for applications requiring frequent cleaning or maintenance, such as the food and pharmaceutical industries.

3. Cost-Effectiveness

The cost of forging large flanges is eliminated, reducing the manufacturing cost of the instrument itself.

4. Preventing Leak Points

Traditional flange connections have four potential leak points (two flange faces and two gaskets). Wafer-type systems, on the other hand, typically use only two gaskets between the flowmeter and the pipeline flange, reducing the potential risk of leaks.

The wafer-type design is ideal for the following applications:

- Food, beverage, dairy, and pharmaceutical industries

These industries have extremely high hygiene requirements, requiring frequent CIP (cleaning-in-place) or SIP (sterilization-in-place) operations and quick disassembly of the instrument for manual cleaning and inspection. The wafer-type design’s easy disassembly perfectly meets this need. Linings are often made of smooth, non-toxic, and corrosion-resistant materials such as polytetrafluoroethylene (PTFE) or PFA.

Used for medium- and low-pressure conveying of corrosive chemicals, requiring regular inspection or replacement of the lining and electrodes.

- Water Treatment and General Industrial Processes

Suitable for measuring medium- and low-pressure media such as clean water, slurries, and wastewater, especially when cost-effective and convenient measurement is required in small-diameter pipelines.

- Projects with limited budgets and installation space.

The wafer-style magnetic flow meter is also designed and manufactured according to Faraday’s Law of Electromagnetic Induction, and its composition and function are the same as the flange-type electromagnetic flowmeter. The difference is that the sensor adopts a non-blue design, compact structure, and light weight. The housing is made of all stainless steel. The shorter measuring tube is conducive to removing dirt on the tube wall and is easy to install and clean.

The wafer-style magnetic flow meter is also designed and manufactured according to Faraday’s Law of Electromagnetic Induction, and its composition and function are the same as the flange-type electromagnetic flowmeter. The difference is that the sensor adopts a non-blue design, compact structure, and light weight. The housing is made of all stainless steel. The shorter measuring tube is conducive to removing dirt on the tube wall and is easy to install and clean.