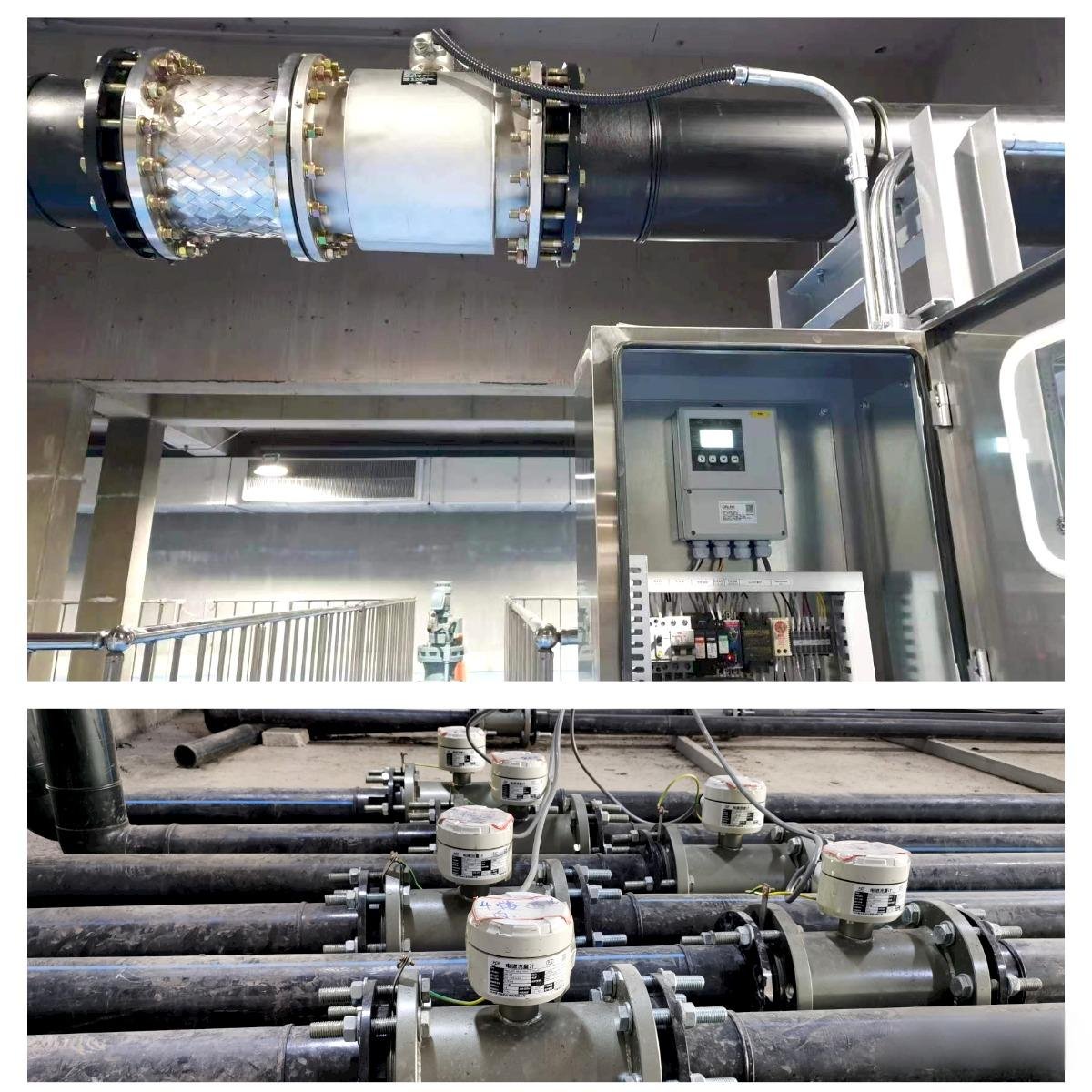

If the on-site environment is complex, the medium process temperature is high, the sensor is easily submerged in water, or remote monitoring is required, a split-type magnetic water flow meter is usually a more suitable and reliable choice.

If the on-site environment is complex, the medium process temperature is high, the sensor is easily submerged in water, or remote monitoring is required, a split-type magnetic water flow meter is usually a more suitable and reliable choice.

Principle

According to Faraday’s principle of electromagnetic induction, a pair of detection electrodes is installed on the tube wall perpendicular to the axis of the measuring tube and the magnetic field lines. When the conductive liquid moves along the axis of the measuring tube, it cuts the magnetic field lines and generates an induced potential. This induced potential is detected by the two detection electrodes, and the value is proportional to the flow rate. Its value is

Its value is

E=KBVD

In the formula:

E-induced potential;

K-Coefficient related to magnetic field distribution and axial length;

B-Magnetic induction intensity;

V-average flow velocity of conductive liquid;

D-electrode spacing;(Measuring the inner diameter of the tube).

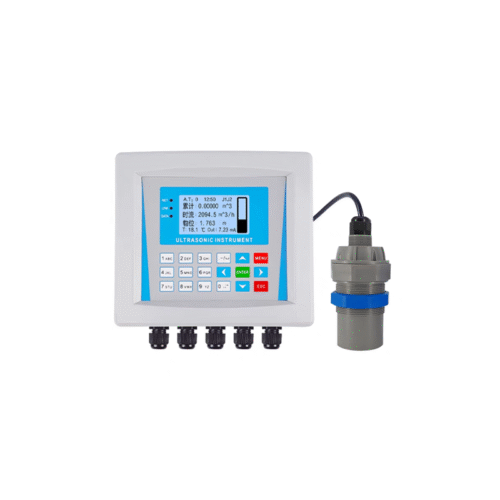

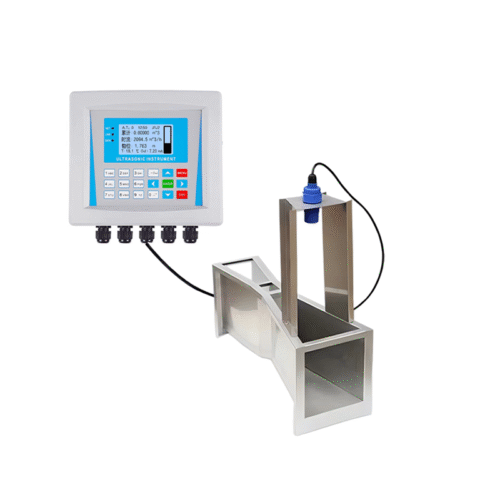

The sensor uses the induced potential E as a flow signal, which is transmitted to the converter. After amplification, transformation, filtering, and a series of digital processing, the instantaneous and cumulative flow rates are displayed on a back-lit dot matrix LCD. The converter has 4-20mA output, alarm output, and frequency output, and is equipped with communication interfaces such as RS-485, and supports HART and MODBUS protocols.

The main advantages of a split electromagnetic flowmeter:

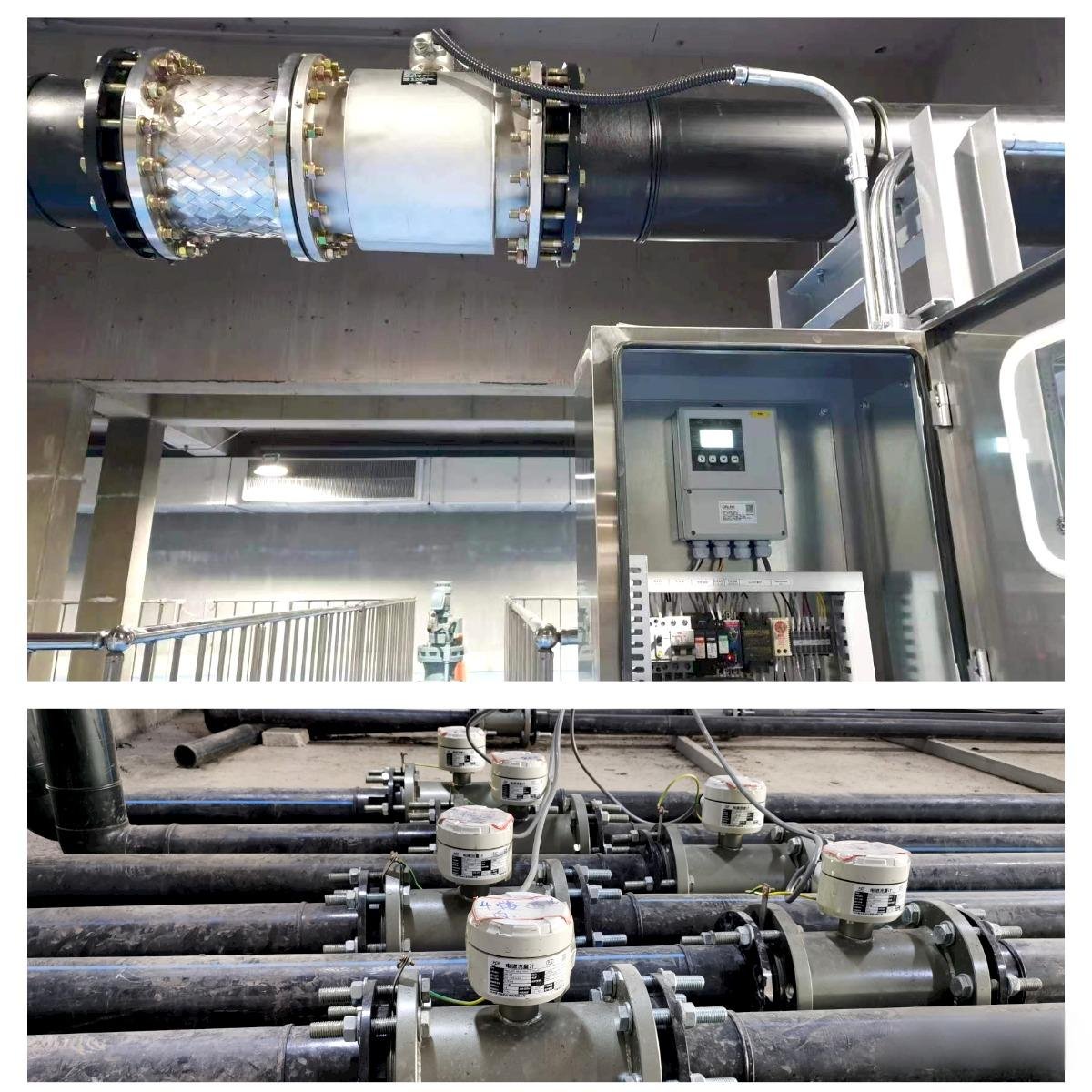

- Adaptability to harsh environments: This is its most prominent advantage. The converter can be installed away from measurement points exposed to high temperatures, high humidity, strong vibrations, corrosive or explosive environments, significantly improving the lifespan and reliability of the electronic components.

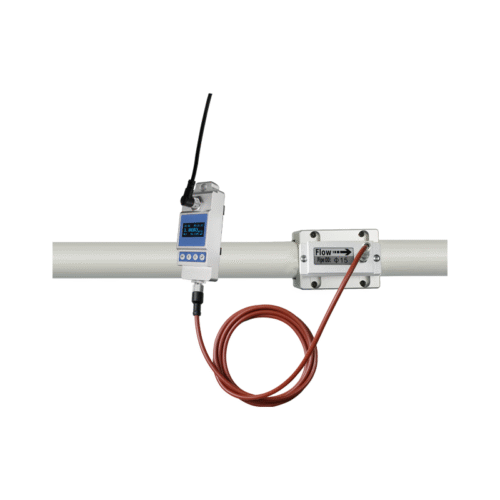

- Easy maintenance and commissioning: Technicians can set parameters, calibrate, and troubleshoot the converter from a comfortable and safe control room, eliminating the need to visit the hazardous measurement site.

- Mounting flexibility: For large-diameter pipelines or installations with limited space, the bulky sensor can be mounted on the pipe while the lightweight converter is installed in a more convenient location.

- Reduced signal attenuation: Although the sensor and converter are separate, the dedicated shielded cable effectively resists external electromagnetic interference, ensuring stable signal transmission over long distances.

A split design is almost a must in the following working conditions:

High-temperature media: Protects the transducer from damage when measuring high-temperature fluids (such as hot water or hot slurries).

Harsh environments: Examples include underground wells, humid pump rooms, outdoor locations exposed to direct sunlight and rain, and locations with strong vibration (e.g., near large pumps).

Improperly visible locations: Sensors installed high up in equipment, deep in pipelines, or when remote monitoring is required.

Corrosive or hazardous areas: The transducer can be installed in a safe area, while the sensor is in a hazardous area.

Large-diameter pipes: Because the sensor itself is heavy, separating it from the transducer simplifies installation.

If the on-site environment is complex, the medium process temperature is high, the sensor is easily submerged in water, or remote monitoring is required, a split-type magnetic water flow meter is usually a more suitable and reliable choice.

If the on-site environment is complex, the medium process temperature is high, the sensor is easily submerged in water, or remote monitoring is required, a split-type magnetic water flow meter is usually a more suitable and reliable choice. Its value is

Its value is