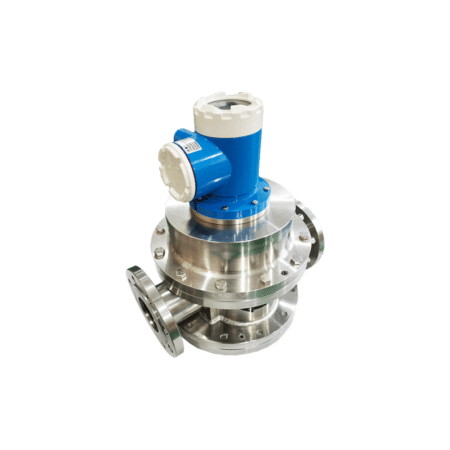

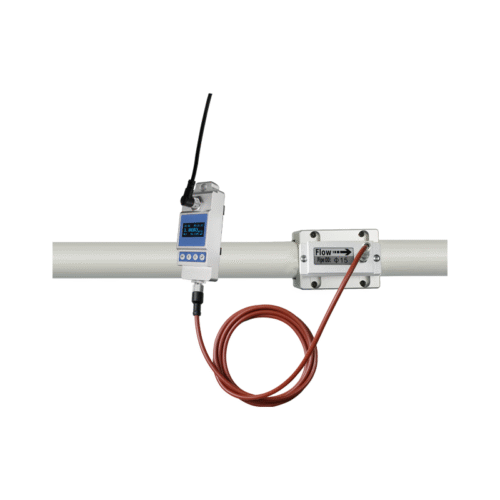

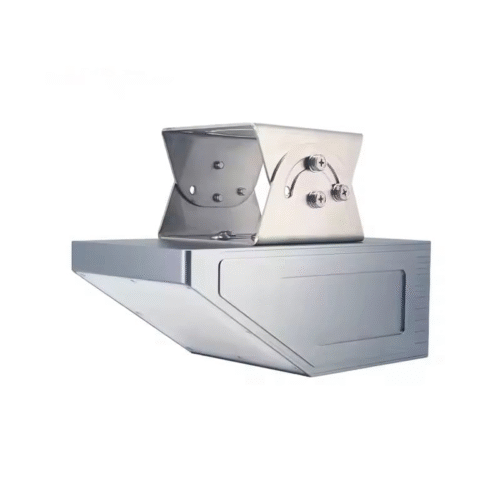

The oval gear flow meter can be customized according to your requirements. Different liquid (acid, alkali, salt, oil, organic solution, etc.) flow meter bodies can be made of different materials. By equipping the flow meter with a signaling device and electronic display, it can achieve centralized remote control of cumulative, quantitative, and instantaneous flow. A liquid crystal digital counter enables on-site display of real-time and total flow, while supporting remote transmission through pulse, current, or communication signals. With a radiator or gear teeth design, it can also handle high-temperature and highly viscous liquids. Thermal insulation jackets can be installed to conduct heat tracing and insulation of the flow meter.

The oval gear flow meter can be customized according to your requirements. Different liquid (acid, alkali, salt, oil, organic solution, etc.) flow meter bodies can be made of different materials. By equipping the flow meter with a signaling device and electronic display, it can achieve centralized remote control of cumulative, quantitative, and instantaneous flow. A liquid crystal digital counter enables on-site display of real-time and total flow, while supporting remote transmission through pulse, current, or communication signals. With a radiator or gear teeth design, it can also handle high-temperature and highly viscous liquids. Thermal insulation jackets can be installed to conduct heat tracing and insulation of the flow meter.

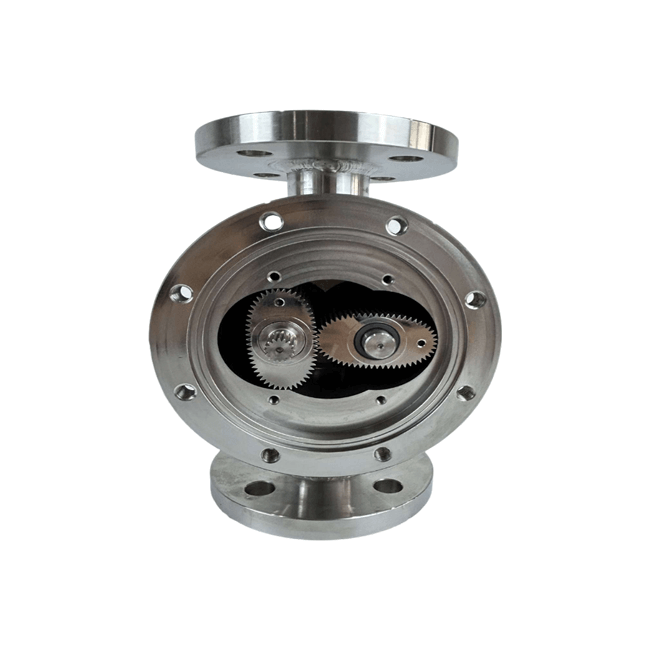

Flow measurement has nothing to do with the flow state of the fluid, because the oval gear flow meter relies on the pressure head of the medium to be measured to push the oval gear to rotate. The higher the viscosity of the medium, the smaller the leakage amount that leaks out from the gear and the measuring space gap. Therefore, the greater the stickiness of the medium under test, the smaller the leakage error, and the more favorable it is to the measurement.

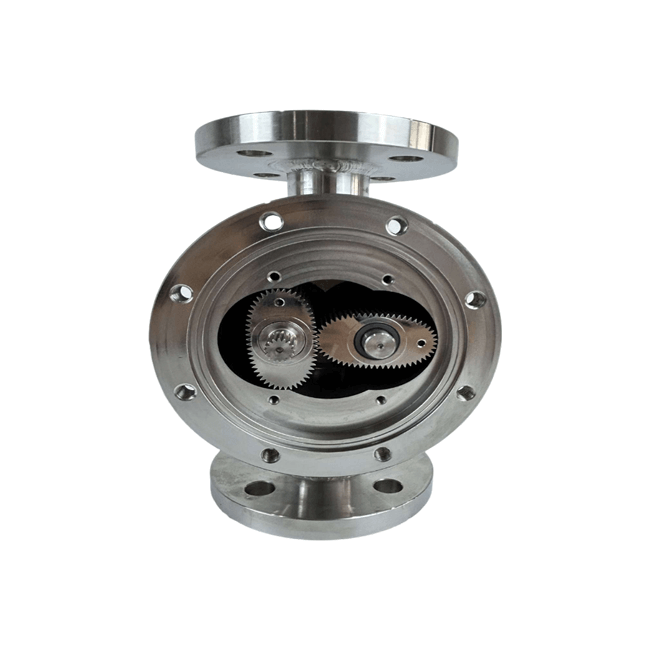

An oval gear flow meter is a type of positive displacement flow meter. It is used for precise continuous or intermittent measurement of the flow or instantaneous flow of liquid in pipelines. It is especially suitable for flow measurement of high viscosity media such as heavy oil, polyvinyl alcohol, and resins.

Oval gear flow meter of iron casting type, cast steel type, and stainless steel type

|

LC—A Iron casting type |

LC—B Stainless steel type |

LC—E Cast steel type |

| Nominal pressure MPa |

1.6 |

1.6, 2.5, 4.0, 6.3 |

1.6, 2.5, 4.0, 6.3 |

| Temperature range ℃ |

Conventional pointer type: -20~+80;High-temperature pointer type: -20~+200;

Conventional LCD type: -20~+60;High-temperature LCD type: -20~+150; |

| Precision level |

0.5% |

| Caliber (mm) |

Viscosity: 0.6—2mPa.s |

Viscosity: 2—200mPa.s |

| 10 |

0.2-0.4 m3/h |

0.08—0.4 m3/h |

| 15 |

0.6-1.5 m3/h |

0.3—1.5 m3/h |

| 20 |

0.8—3 m3/h |

0.6—3 m3/h |

| 25 |

1.2—6 m3/h |

0.8—6 m3/h |

| 40 |

5—15 m3/h |

3—15 m3/h |

| 50 |

6—24 m3/h |

4—24 m3/h |

| 65 |

10—40 m3/h |

8—40 m3/h |

| 80 (light type) |

10—40 m3/h |

8—40 m3/h |

| 80 (heavy type) |

15—60 m3/h |

10—60 m3/h |

| 100 |

30—100 m3/h |

15—100 m3/h |

| 150 |

45—190 m3/h |

34—190 m3/h |

| 200 |

68—340 m3/h |

56—340 m3/h |

Oval gear flow meter of high viscosity type

|

LC—NA High-viscosity iron casting type |

LC—NE High-viscosity cast steel type |

LC-NB High-viscosity stainless steel type |

| Nominal pressure(MPa) |

1.6 |

1.6、2.5、4.0、6.3 |

1.6、2.5、4.0、6.3 |

| Temperature range ℃ |

Conventional pointer type: -20~+80;High-temperature pointer type: -20~+200;

Conventional LCD type: -20~+60;High-temperature LCD type: -20~+150; |

| Precision level |

0.5% |

| Flow range m3/h |

| Caliber (mm) |

Viscosity: 200—1000mPa.s |

Viscosity: 1000-2000mPa.s |

| 10 |

0.04—0.3 m3/h |

0.03-0.2 m3/h |

| 15 |

0.2—1.0 m3/h |

0.1-0.7 m3/h |

| 20 |

0.4—2.1 m3/h |

0.25-1.5 m3/h |

| 25 |

0.6-4.2 m3/h |

0.6-3 m3/h |

| 40 |

2.1—10.5 m3/h |

1.0-7.5 m3/h |

| 50 |

2.4-16.8 m3/h |

2-12 m3/h |

| 65 |

6-28 m3/h |

4-20 m3/h |

| 80 (light type) |

6-28 m3/h |

4-20 m3/h |

| 80 (heavy type) |

8-42 m3/h |

6-30 m3/h |

| 100 |

10-70 m3/h |

10-50 m3/h |

| 150 |

27-133 m3/h |

19-95 m3/h |

| 200 |

48-238 m3/h |

34-170 m3/h |

High-precision oval gear flow meter (precision: 0.2%)

|

LC—A Iron casting type |

LC—B Stainless steel type |

LC—E Cast steel type |

| NominalpressureMPa |

1.6 |

1.6、2.5、4.0、6.3 |

1.6、2.5、4.0、6.3 |

| Temperature range ℃ |

Conventional pointer type: -20~+80;High-temperature pointer type: -20~+200;

Conventional LCD type: -20~+60;High-temperature LCD type: -20~+150; |

| Precision level |

0.2% |

| Flow range m3/h |

| Caliber (mm) |

0.6—2 mPa.s |

2—200 mPa.s |

| 10 |

|

0.2—0.4 m3/h |

| 15 |

|

0.5—1.5 m3/h |

| 20 |

1.5—3 m3/h |

1—3 m3/h |

| 25 |

3—6 m3/h |

1.2—6 m3/h |

| 40 |

8—15 m3/h |

5—15 m3/h |

| 50 |

12—24 m3/h |

8—24 m3/h |

| 65 |

20—40 m3/h |

10—40 m3/h |

| 80 (light type) |

20—40 m3/h |

10—40 m3/h |

| 80 (heavy type) |

30—60 m3/h |

15—60 m3/h |

| 100 |

40—100 m3/h |

20—100 m3/h |

| 150 |

90—190 m3/h |

56—190 m3/h |

| 200 |

170—340 m3/h |

68—340 m3/h |

High-precision and high-viscosity oval gear flow meter (precision: 0.2%)

|

LC—NA High-viscosity iron casting type |

LC—NE High-viscosity cast steel type |

LC-NB High-viscosity stainless steel type |

| NominalpressureMPa |

1.6 |

1.6, 2.5, 4.0, 6.3 |

1.6, 2.5, 4.0, 6.3 |

| Temperature range ℃ |

Conventional pointer type: -20~+80; High-temperature pointer type: -20~+200;

Conventional LCD type: -20~+60; High-temperature LCD type: -20~+150; |

| Precision grade |

0.2% |

| Flow range m3/h |

| Caliber (mm) |

Viscosity: 200—1000mPa.s |

Viscosity: 1000-2000mPa.s |

| 10 |

0.08—0.3 m3/h |

0.06-0.2 m3/h |

| 15 |

0.3—1.0 m3/h |

0.2-0.7 m3/h |

| 20 |

0.6—2.1 m3/h |

0.5-1.5 m3/h |

| 25 |

1-4.2 m3/h |

0.8-3 m3/h |

| 40 |

3—10.5 m3/h |

2-7.5 m3/h |

| 50 |

4-16.8 m3/h |

3-12 m3/h |

| 65 |

8-28 m3/h |

6-20 m3/h |

| 80 (light type) |

8-28 m3/h |

6-20 m3/h |

| 80 (heavy type) |

10-42 m3/h |

8-30 m3/h |

| 100 |

15-70 m3/h |

12-50 m3/h |

| 150 |

34-133 m3/h |

30-95 m3/h |

| 200 |

56-238 m3/h |

50-170 m3/h |

The oval gear flow meter is mainly used to measure high-viscosity media. Its products are widely used in petroleum, petrochemical, natural gas, chemical, paper-making, food, and other industries.

The oval gear flow meter can be customized according to your requirements. Different liquid (acid, alkali, salt, oil, organic solution, etc.) flow meter bodies can be made of different materials. By equipping the flow meter with a signaling device and electronic display, it can achieve centralized remote control of cumulative, quantitative, and instantaneous flow. A liquid crystal digital counter enables on-site display of real-time and total flow, while supporting remote transmission through pulse, current, or communication signals. With a radiator or gear teeth design, it can also handle high-temperature and highly viscous liquids. Thermal insulation jackets can be installed to conduct heat tracing and insulation of the flow meter.

The oval gear flow meter can be customized according to your requirements. Different liquid (acid, alkali, salt, oil, organic solution, etc.) flow meter bodies can be made of different materials. By equipping the flow meter with a signaling device and electronic display, it can achieve centralized remote control of cumulative, quantitative, and instantaneous flow. A liquid crystal digital counter enables on-site display of real-time and total flow, while supporting remote transmission through pulse, current, or communication signals. With a radiator or gear teeth design, it can also handle high-temperature and highly viscous liquids. Thermal insulation jackets can be installed to conduct heat tracing and insulation of the flow meter.