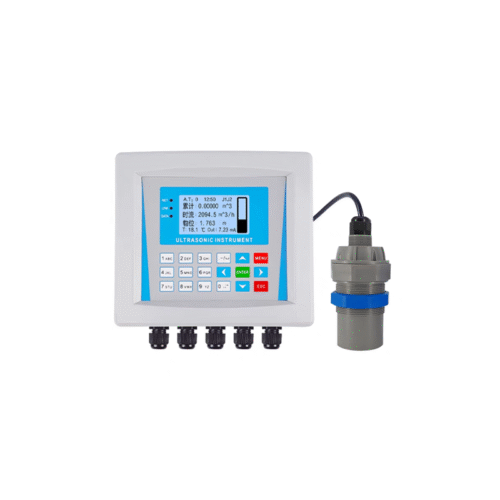

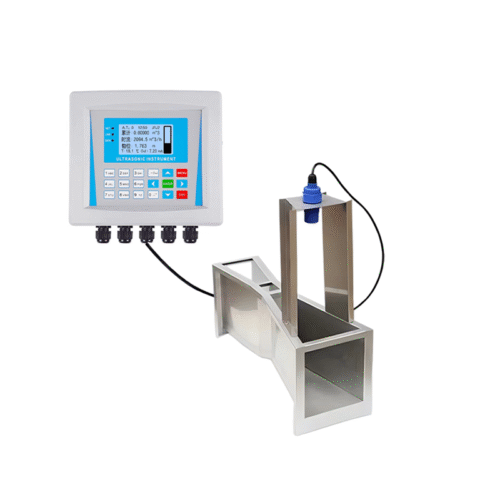

The QYF-D10 Doppler open channel flow meter calculates frequency changes based on the Doppler effect to measure flow velocity, while also enabling water level and water temperature measurement. Its housing is constructed from ABS engineering plastic, ensuring robust impact resistance and reliable waterproof sealing. Equipped with RS485 communication functionality, it supports remote data transmission with excellent stability and reliability.

Boasting a compact size, high precision, a lightweight design, and an extensive measurement range, this device is suitable for flow velocity measurement scenarios across diverse industries. It finds wide application in open channels, rivers, and non-full pipe flow metering and monitoring systems. Supports both unidirectional and bidirectional measurement technologies.

Working Principle of the Doppler Ultrasonic Flow Meter

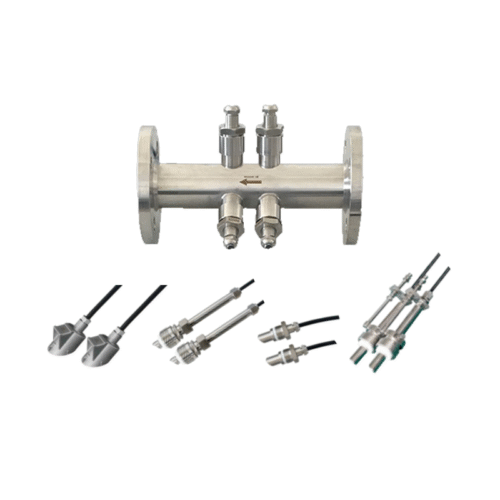

Ultrasonic waves are sound waves with frequencies exceeding 20,000 Hz, characterized by excellent directionality and strong penetration capabilities. In Doppler ultrasonic flow velocity measurement technology, ultrasonic waves serve as the carrier for measuring fluid flow velocity.

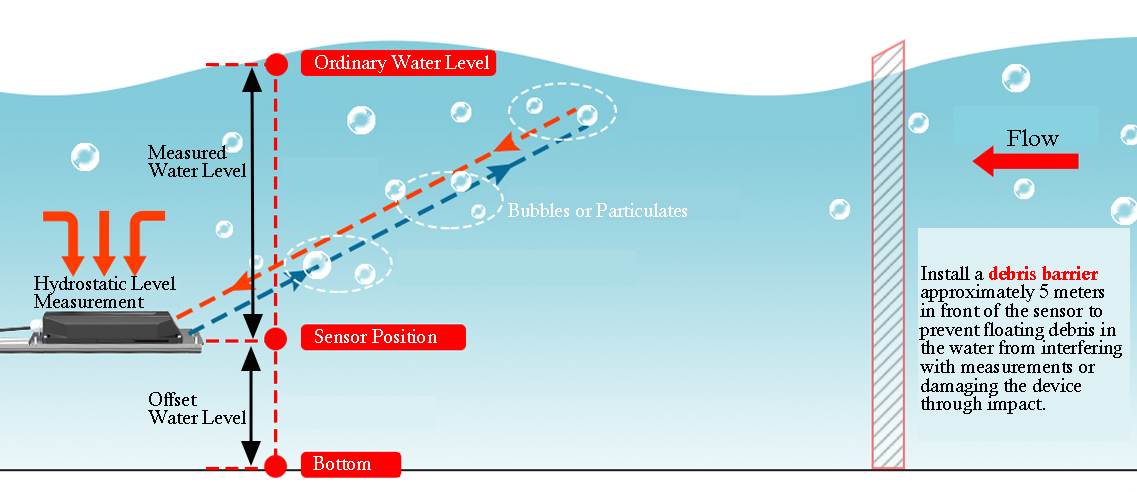

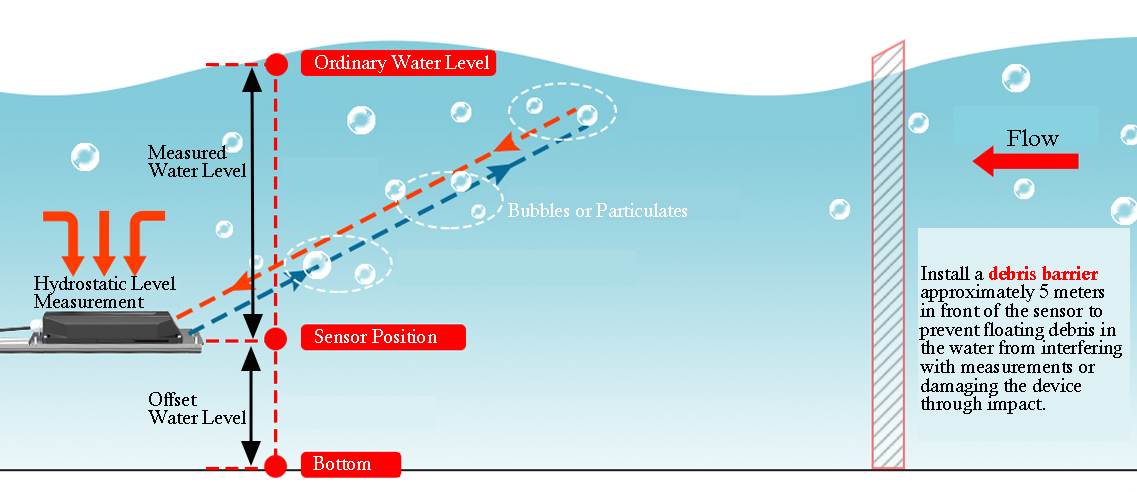

The Doppler open channel flow meter emits ultrasonic waves of a specific frequency into the fluid. If the fluid is stationary, the frequency of the reflected ultrasonic waves will match the emitted frequency. However, when the fluid is in motion, the scenario changes. Particles within the fluid (such as micro-particles in water) move along with the fluid, acting as individual moving “secondary wave sources.”

When the emitted ultrasonic waves encounter these moving particles, reflection occurs. Due to the relative motion between the particles and the ultrasonic wave source, the frequency of the reflected ultrasonic waves shifts in accordance with the Doppler effect. By measuring the frequency difference between the emitted and reflected ultrasonic waves—known as the Doppler shift—the movement velocity of particles in the fluid can be accurately calculated, thereby deriving the fluid flow velocity.

This device is primarily applied in irrigation open channels, municipal sewer pipelines, and hydrological basins. It is particularly suited for low-water-level environments, with an optimal water level of approximately 20 centimeters and a minimum requirement of 5 centimeters. For regular pipes and channels, the device integrates a built-in temperature compensation module. It measures water depth via a hydrostatic level sensor and flow velocity using an ultrasonic Doppler flow sensor, enabling accurate calculation of flow rate.