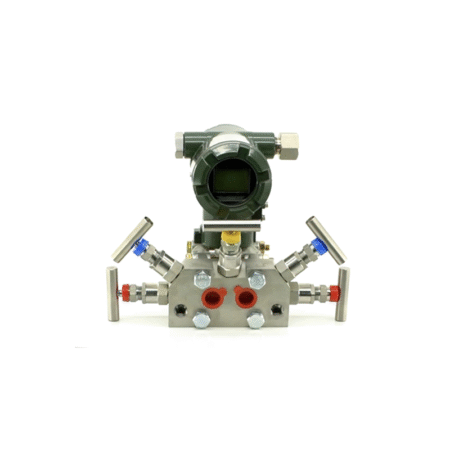

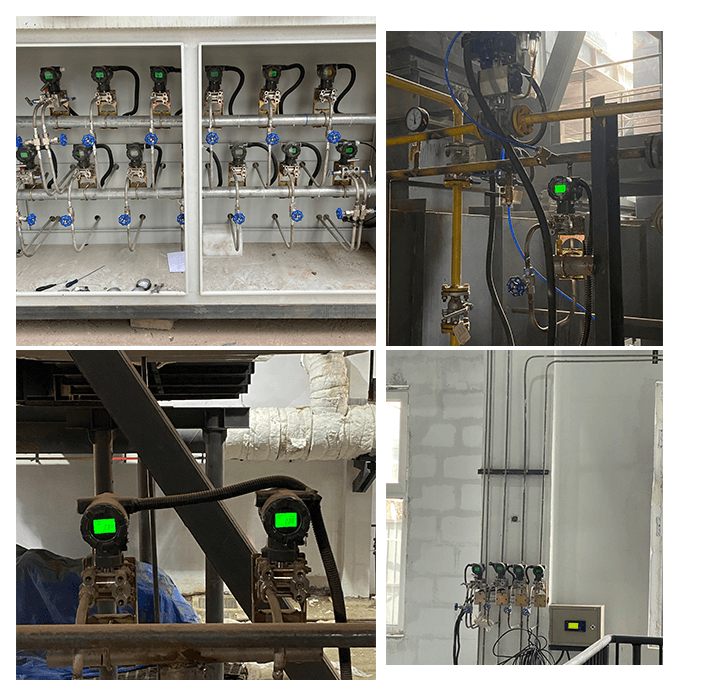

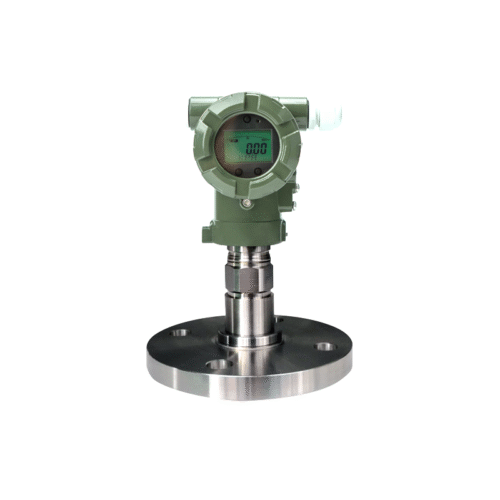

The pressure differential transmitter is a device that measures the pressure difference between two points and converts the difference into a standard electrical signal (such as 4-20mA or digital signal) for transmission to a control system or display device.

The pressure differential transmitter is a device that measures the pressure difference between two points and converts the difference into a standard electrical signal (such as 4-20mA or digital signal) for transmission to a control system or display device.

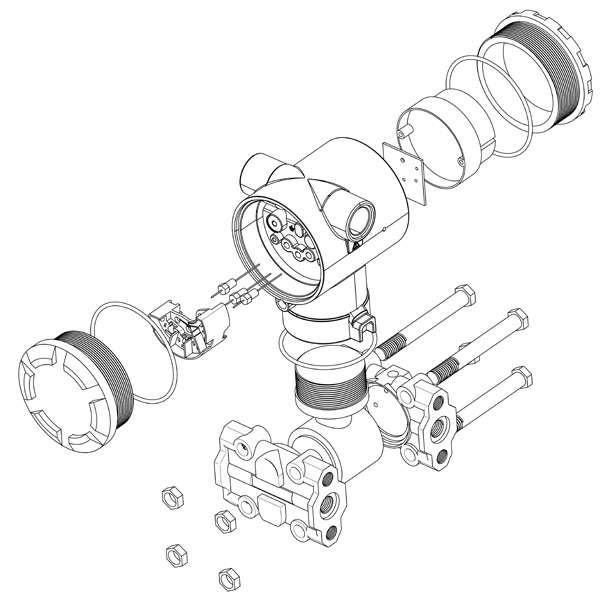

Principle of the pressure differential transmitter

The two pressures of the medium to be measured pass into the high and low pressure chambers, act on the isolation diaphragms on both sides of the delta element, and are transmitted to both sides of the measurement diaphragm through the isolation diaphragm and the filling liquid in the element. The electrodes on the measurement diaphragm and the insulation sheets on both sides each form a capacitor.

When the pressures on both sides are inconsistent, the measurement diaphragm will displace, and the displacement is proportional to the pressure difference. Therefore, the capacitances on both sides are unequal and are converted into signals proportional to the pressure through the oscillation and demodulation links. Pressure transmitters and absolute pressure transmitters work on the same principle as differential pressure transmitters, except that the pressure in the low-pressure chamber is atmospheric pressure or vacuum.