In the pharmaceutical industry, cleanliness and process safety are critical. A clamp on ultrasonic flow meter is the ideal solution for hygienic flow measurement because it does not require pipe cutting, welding, or direct contact with the process fluid. By using external ultrasonic sensors, a portable ultrasonic flow meter ensures contamination-free and highly accurate flow monitoring in pharmaceutical applications.

What is Clmap on Ultrasonic Flow Meter

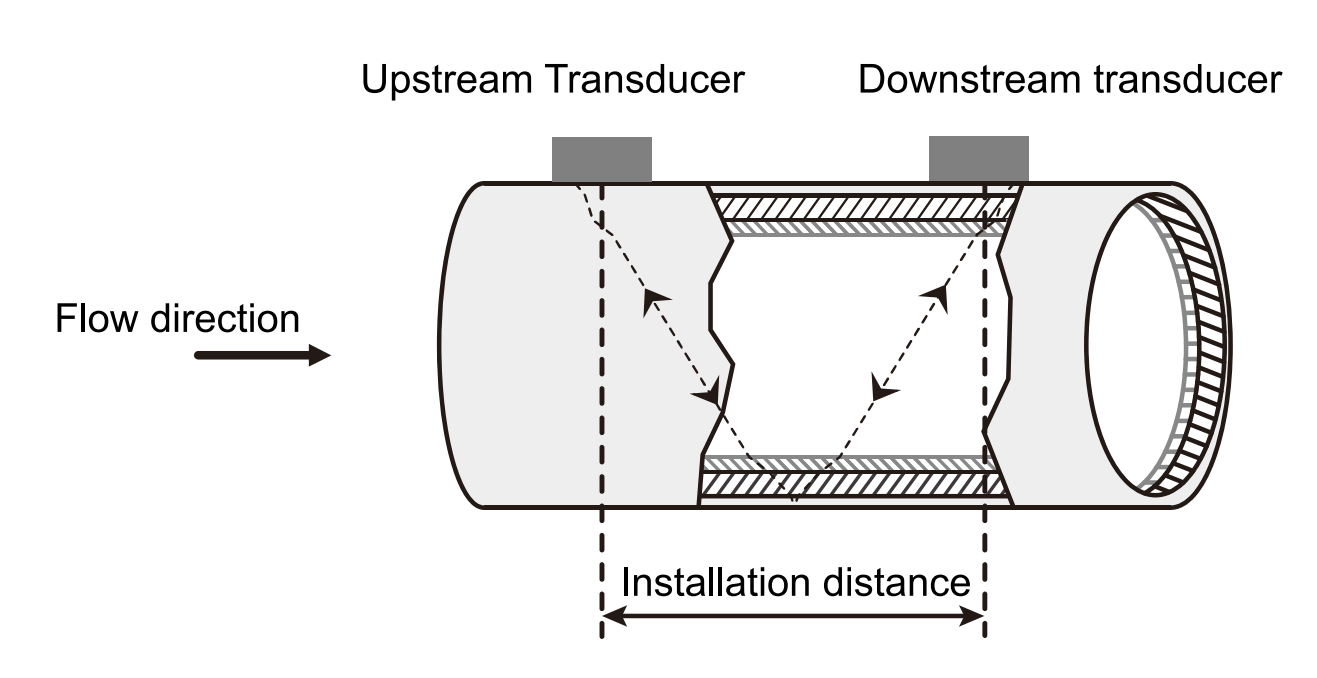

The clamp on ultrasonic flow meter is a non-invasive flow measurement device that uses ultrasonic signals to accurately calculate flow velocity through the pipe wall. This type of ultrasonic flow meter operates based on the transit-time (time-difference) measurement principle.

Ultrasonic waves transmitted in the direction of fluid flow travel faster downstream and slower upstream. As a result, the ultrasonic signals experience different propagation times over the same transmission path. By precisely measuring this time difference, the ultrasonic water flow meter calculates the fluid flow velocity and volumetric flow rate with high accuracy.

Unlike traditional inline flow meters, the portable ultrasonic flow meter is installed externally on the pipe surface. This non-contact installation ensures zero interference with the internal flow, no pressure loss, and no risk of contamination.

Because of its hygienic, non-invasive design, the portable ultrasonic flow meter is particularly well-suited for applications where cleanliness, system integrity, and operational safety are critical.

Want to Know More About this Ultrasonic Flow Meter or its Pricing?

Our engineers will recommend the most suitable model based on your specs and budget.

When to use Ultrasonic Flow Sensors

Since its introduction to the market, the external ultrasonic flow meter has been widely used in the cleaning equipment industry. Due to its simple installation and operation, as well as reliable measurement performance, it is continuously being promoted in new industries. Currently, its main application industries include semiconductors, food, pharmaceuticals, beverages, detergents, printing and dyeing, and chemical products.

Its main applications are in the metering and control of water (tap water, pure water, ultrapure water), and due to the continuous promotion of its application industries, it has also been well applied to various acids, alkalis, organic liquids, chemical solvents, alcohol, beverage water, etc.

Clamp on ultrasonic flow meters deliver excellent performance in measuring flow in a wide range of small-diameter pipes.

In addition, due to their compact size, ease of installation, and accurate, stable performance, the portable ultrasonic flow sensors are well-suited for large-scale production and widespread use across a range of precision and high-end industries.

Wondering Whether This Clamp-on Ultrasonic Flow Meter is the Right Solution for your Application?

Our engineers will recommend the most suitable model based on your specs and budget.

External Sensor Installation for Maximum Hygiene

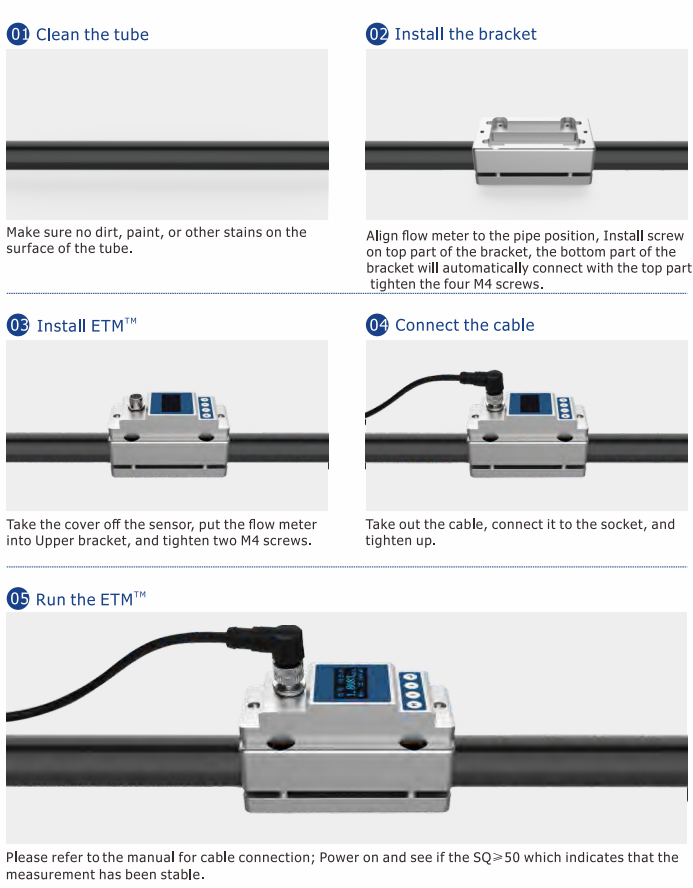

The flow sensors are mounted externally on the pipe surface.

These sensors are compatible with various pipe materials, including stainless steel, plastic, and hygienic tubing commonly used in pharmaceutical systems.

With external installation:

The flowing medium remains completely untouched

There is zero risk of chemical or biological contamination

The portable ultrasonic flow meter can be relocated easily for temporary measurements

This flexibility makes the clamp on ultrasonic flow meter ideal for both permanent monitoring and short-term testing.

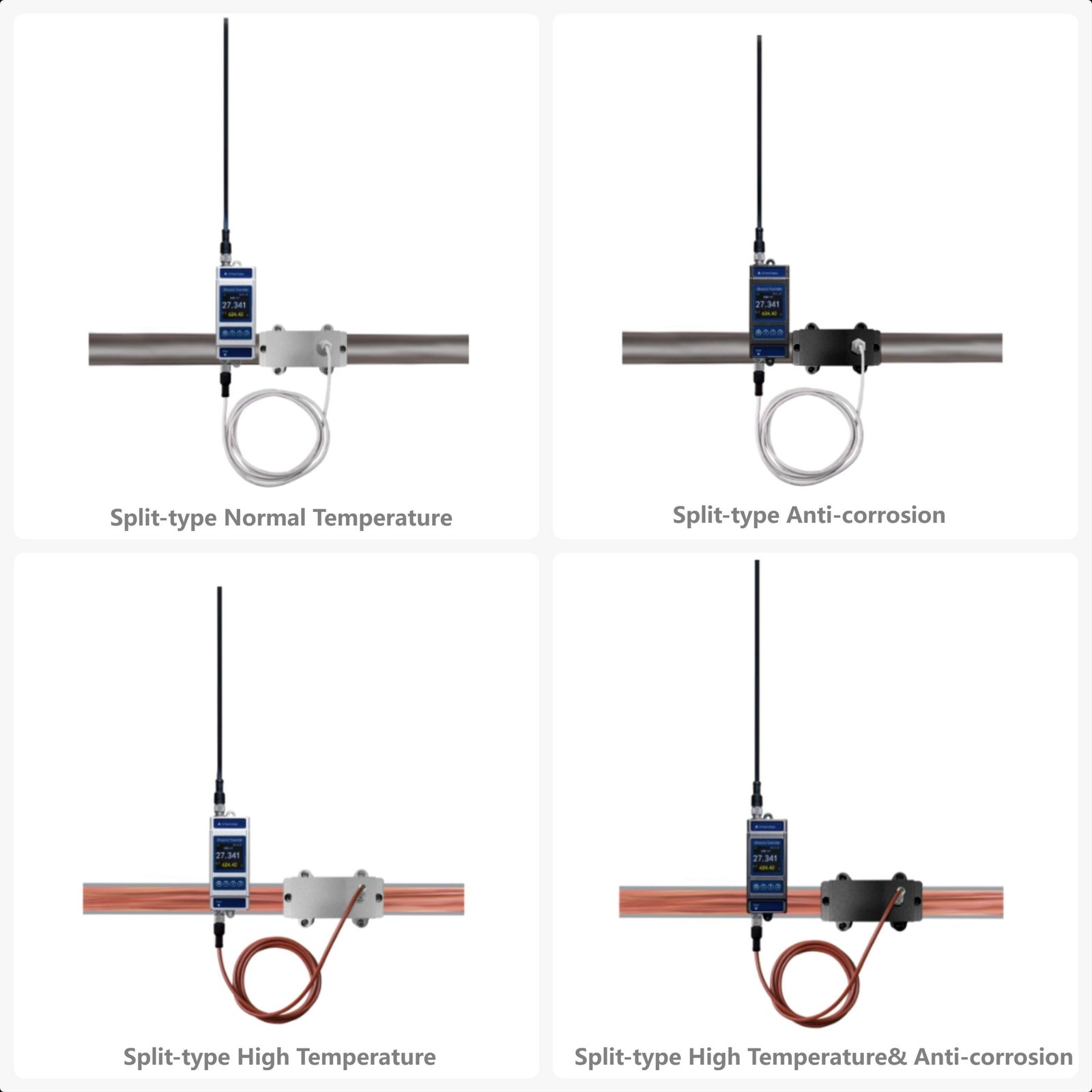

Types of Clamp-on Ultrasonic Flow Sensors

A diverse range of non-contact ultrasonic flow sensors is available, with each model engineered to suit distinct applications, operating environments, and fluid media. Feel free to contact us for tailored product guidance and support.

In summary, clamp on ultrasonic flow meters provide a highly hygienic, non-invasive, and accurate solution for flow measurement in industries where cleanliness and process integrity are paramount. Their external installation eliminates the risk of contamination, pressure loss, or interference with the fluid, making them ideal for pharmaceuticals, food and beverages, semiconductors, and other high-precision applications. With versatile compatibility across pipe materials and easy portability, these ultrasonic flow sensors offer both permanent monitoring and temporary measurement solutions. For optimized performance and tailored recommendations, consulting with experienced engineers ensures the right clamp-on ultrasonic flow meter is selected to meet your specific operational and hygiene requirements.