Ultrasonic level sensors have become an indispensable measurement solution across the chemical and water treatment industries due to their non-contact measurement principle, high reliability, and strong adaptability to harsh media. Especially in applications involving corrosive, viscous, volatile, or contaminated liquids, ultrasonic level sensors provide accurate, stable, and maintenance-friendly level measurement.

This article provides an in-depth overview of applications, selection criteria, product structure, working principles, technical parameters, and various models of ultrasonic level sensors, helping engineers and system integrators make informed decisions.

Working Principle of Ultrasonic Level Sensor

Ultrasonic level sensors operate based on the time-of-flight (TOF) principle, leveraging high-frequency sound waves to measure the distance between the sensor and the liquid surface. Here’s a step-by-step breakdown of their working mechanism.

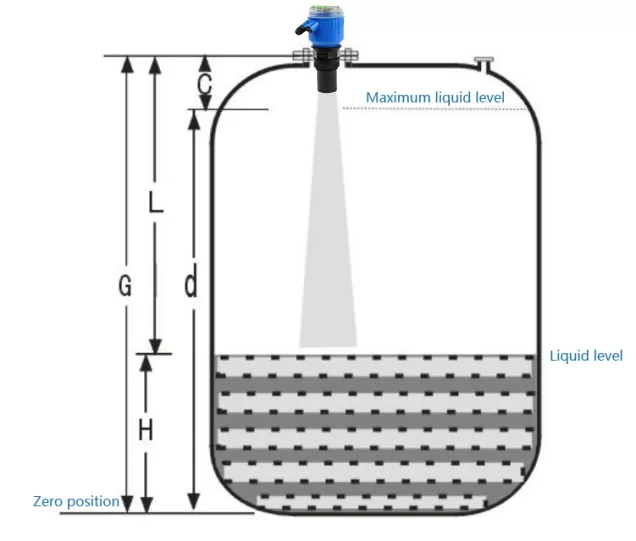

Install height G: ( probe to the tank bottom)

Liquid level H: ( level or material level height)

Air distance L: (probe to test surface area)

Blanking distance C: (a small area below the sensor)

Instrument range d: (generally from zero to the highest plane, only linearly corresponding to output P)

Formula:

1、Ranging:L=S*T/2; S=331.45+0.61*n℃

2、Level:H=G-L

3、Output: P=H/d*16+4 or P=L/d*16+4 (Note: P output current in mA)

- The sensor’s transducer (a key component) emits high-frequency ultrasonic waves (typically 20 kHz to 200 kHz) toward the liquid surface.

- These sound waves travel through the air (or gas) above the liquid, reflect off the liquid surface, and return to the transducer.

- The sensor’s built-in microprocessor calculates the time elapsed between the emission and reception of the sound waves.

- Using the speed of sound in the medium (compensated for temperature, pressure, and humidity variations), the sensor converts the time difference into a precise distance measurement. The liquid level is then derived by subtracting this distance from the total height of the tank or container.

The non-contact method ensures no mechanical wear, no medium contamination, and high operational reliability.

Want to Know More About this Ultrasonic Level Sensor or its Pricing?

Our engineers will recommend the most suitable model based on your specs and budget.

Structural Components of Ultrasonic Level Transmitter

Besides the housing, display panel, electronic connector, sealing gasket, and other components, a standard ultrasonic level sensor comprises four core components, each playing a vital role in ensuring accurate and reliable operation.

- Ultrasonic Level Transducer (Probe): The heart of the sensor, responsible for emitting and receiving ultrasonic waves. Transducers are typically made of corrosion-resistant materials (e.g., plastic, PVDF, PTFE, or stainless steel) to withstand harsh chemical environments. For explosive or high-temperature scenarios, transducers may be equipped with explosion-proof casings or high-temperature shields.

- Microprocessor: Processes the time-of-flight data, compensates for environmental factors (e.g., temperature, pressure), and converts raw data into usable level readings. Advanced microprocessors also enable features like self-diagnosis, data logging, and remote communication.

- Power Supply Module: Provides stable power to the sensor, supporting various input voltages (e.g., 24VDC, 220VAC). Low-power models are available for battery-operated or remote applications.

- Communication Interface: Facilitates data transmission to control systems (e.g., DCS, SCADA) or mobile devices. Common interfaces include RS485 (Modbus protocol), 4-20mA analog output, and 4G/Wi-Fi for wireless remote monitoring.

Key Technical Parameters of Ultrasonic Level Meter

When selecting an ultrasonic liquid level meter, understanding its technical parameters is crucial to ensure compatibility with your application. Below are the most critical specifications:

- Measurement Range: The minimum and maximum distance the sensor can measure. Ranges typically vary from 0.1m to 30m (for standard models). Note that the sensor’s “blind zone” (the minimum distance from the transducer to the liquid surface where measurement is unavailable) must be considered—blind zones usually range from 6cm to 50cm, depending on the model.

- Measurement Medium: Probes of different materials should be selected for different media.

- Measurement Accuracy: Indicates the sensor’s precision, often expressed as a percentage of full scale (FS) or absolute error. Industrial-grade sensors offer accuracy of ±0.25% FS to ±1% FS.

- Operating Temperature Range: The temperature range in which the sensor can function reliably. Standard models operate between -20°C and 55°C, while high-temperature variants (for chemical reactors or steam tanks) can withstand -40°C to 110°C.

- Operating Pressure Range: Suitable for atmospheric pressure (most standard applications) or high-pressure environments (e.g., sealed chemical tanks).

- Protection Rating: Defines the sensor’s resistance to dust, water, and other contaminants. Common ratings include IP65 (dust-tight and water-resistant) and IP68 (fully submersible for short periods), with IP67 being ideal for outdoor or wet industrial settings.

- Output Signals: Determines how the sensor transmits data. Analog outputs (4-20mA) are widely used for direct integration with PLC systems, while digital outputs (RS485, Modbus) support data logging and remote control. Some advanced models offer HART or LoRaWAN communication for IoT integration.

- Application Environments: Different models should be selected for different operating conditions, such as integrated or split-type, normal temperature or high temperature, standard or explosion-proof, etc.

Furthermore, ultrasonic level gauges are not suitable for applications involving wide measurement ranges, vacuum conditions, heavy dust, dense fog, frequent temperature fluctuations, or highly volatile substances. For such scenarios, frequency-modulated 80G radar level transmitters are recommended to deliver more reliable and accurate measurement performance.

Wondering Whether This Ultrasonic Level Meter is the Right Solution for your Application?

Our engineers will recommend the most suitable model based on your specs and budget.

Types of Ultrasonic Level Gauge

Multiple types of non-contact ultrasonic level gauge are offered, with each type tailored to suit distinct applications, environments, or measured materials.

In conclusion, ultrasonic level detection stands out as a cost-effective, reliable, and user-friendly non-contact measurement solution for liquid level monitoring in chemical, water treatment, and various industrial sectors. With their flexible configuration options, robust technical performance, and easy integration with control systems, they cater to the diverse needs of engineers and system integrators alike.

While they have limitations in extreme environments such as high dust, vacuum, or frequent temperature fluctuations—where 80G radar level transmitters are more suitable—ultrasonic level sensors remain the go-to choice for most standard liquid level measurement scenarios. By understanding their working principles, key parameters, and application scope, you can select the optimal model to ensure stable and accurate level monitoring, ultimately enhancing operational efficiency and reducing maintenance costs.

Whether you are upgrading existing measurement systems or designing new industrial solutions, ultrasonic level sensors offer a balance of performance and affordability that is hard to match. For more professional product selection guidance and customized solutions, feel free to reach out to our technical team.