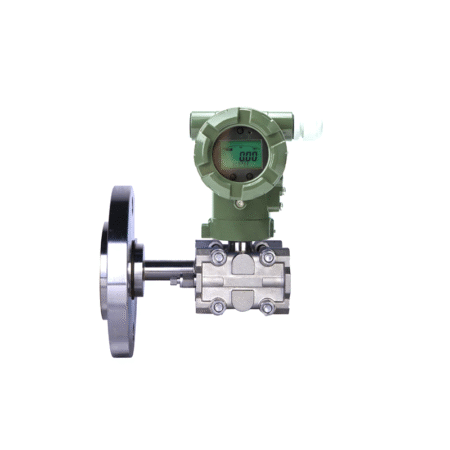

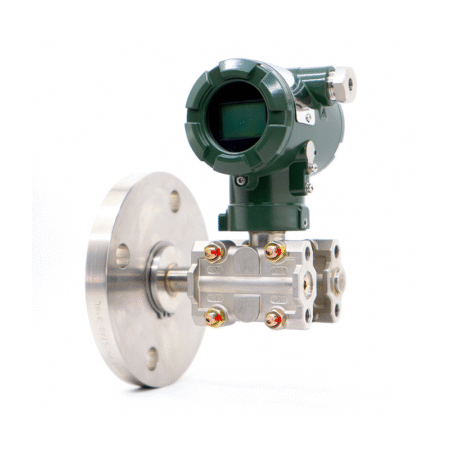

The QYL-3351LT differential pressure level transmitter is a state-of-the-art device developed with advanced international technology and high-quality imported components. Rigorously assembled and tested, this flange-type transmitter features a modern design, a wide range of specifications, and easy installation and operation.

The QYL-3351LT differential pressure level transmitter is a state-of-the-art device developed with advanced international technology and high-quality imported components. Rigorously assembled and tested, this flange-type transmitter features a modern design, a wide range of specifications, and easy installation and operation.

Principle

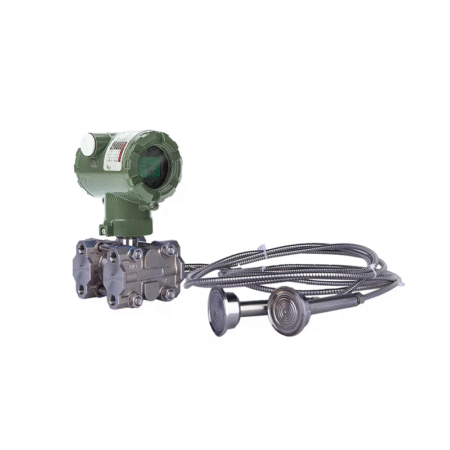

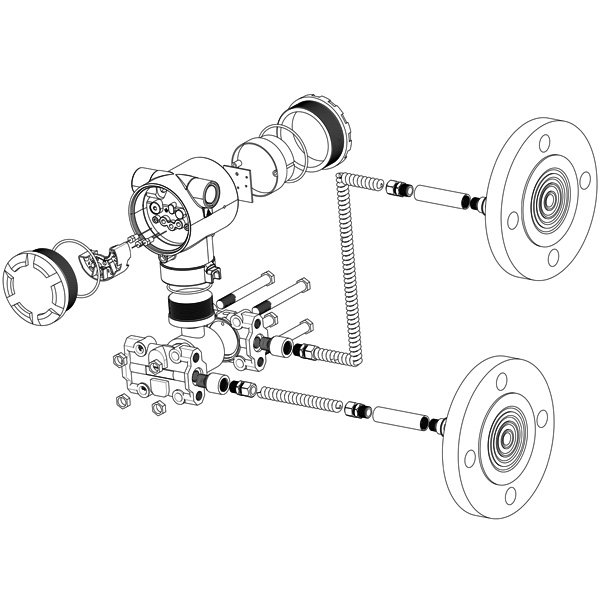

Single and double-flange differential pressure level gauges consist of a differential pressure transmitter, a capillary tube, and a flange with a sealing diaphragm. The role of the sealing diaphragm is to prevent the medium in the pipeline from directly entering the differential pressure transmitter. It is connected to the transmitter by a capillary tube filled with liquid (generally, silicone oil is used).

When the diaphragm is pressed, it will cause slight deformation, and the deformation displacement or frequency is transmitted to the transmitter through the liquid in the capillary tube, which is processed by the transmitter and converted into an output signal. The two pressures of the medium to be measured pass into the high and low pressure chambers, act on the isolation diaphragms on both sides of the delta element (i.e., the sensitive element), and are transferred to both sides of the measuring diaphragm through the isolation diaphragms and the filling liquid in the element.

The measuring diaphragm and the electrodes on both sides form a capacitor. When the pressures on both sides are inconsistent, the measuring diaphragm is displaced, and the displacement is proportional to the pressure difference. Therefore, the capacitances on both sides are unequal and are converted into signals proportional to the pressure through the oscillation and demodulation links.