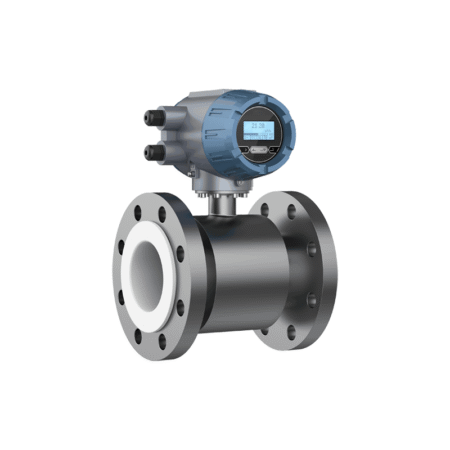

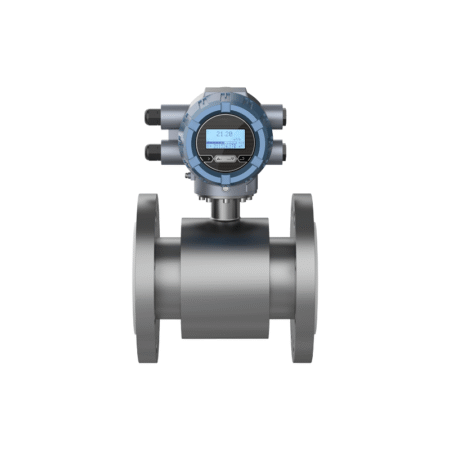

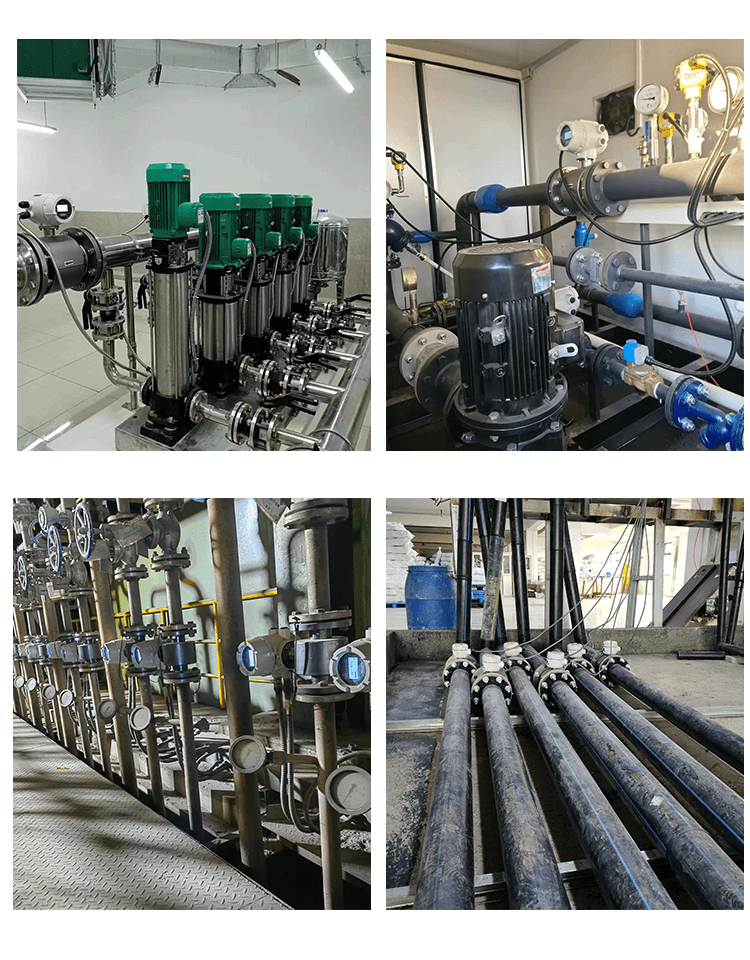

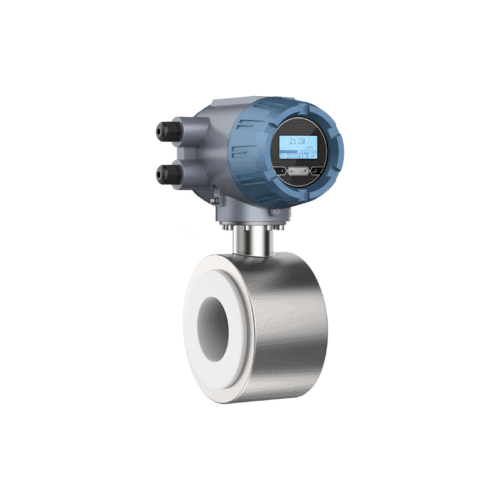

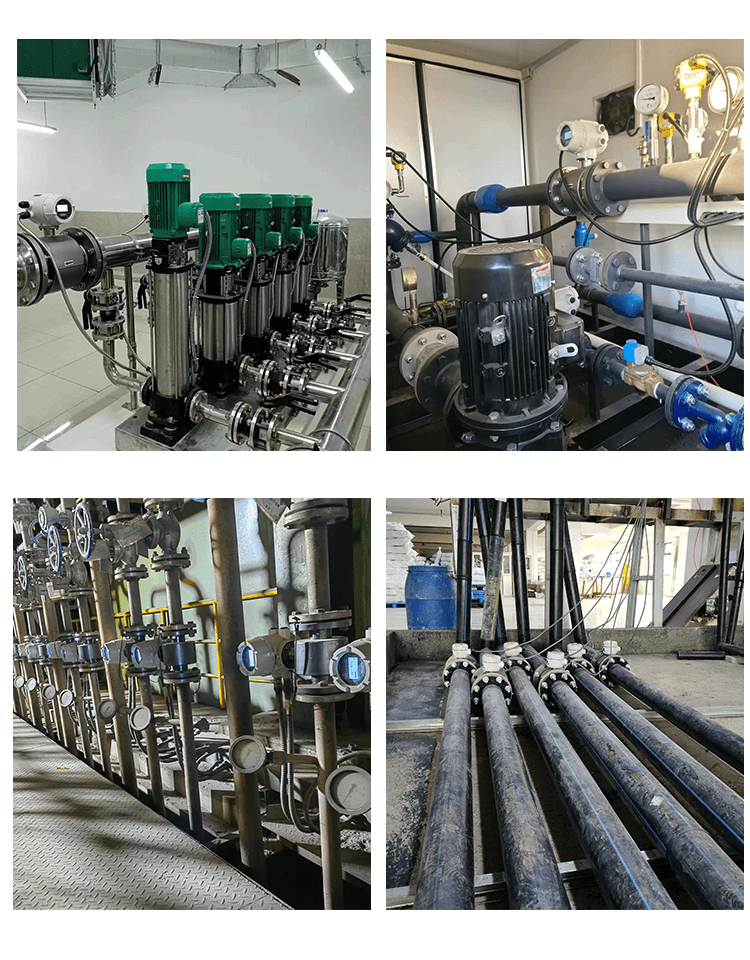

A magnetic water flow meter is a high-precision, high-reliability velocity flow meter, widely used in petroleum, chemical, steel, food, electricity, paper-making, water treatment, water supply, heating, environmental protection, and other industries.

Principle

According to Faraday’s principle of electromagnetic induction, a pair of detection electrodes is installed on the tube wall perpendicular to the axis of the measuring tube and the magnetic field lines. When the conductive liquid moves along the axis of the measuring tube, it cuts the magnetic field lines and generates an induced potential. This induced potential is detected by the two detection electrodes, and the value is proportional to the flow rate. Its value is

Its value is

E=KBVD

In the formula:

E-induced potential;

K-Coefficient related to magnetic field distribution and axial length;

B-Magnetic induction intensity;

V-average flow velocity of conductive liquid;

D-electrode spacing;(Measuring the inner diameter of the tube).

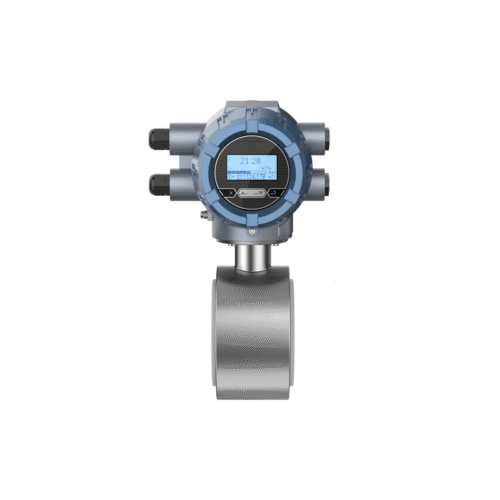

The sensor uses the induced potential E as a flow signal, which is transmitted to the converter. After amplification, transformation, filtering, and a series of digital processing, the instantaneous and cumulative flow rates are displayed on a back-lit dot matrix LCD. The converter has 4-20mA output, alarm output, and frequency output, and is equipped with communication interfaces such as RS-485, and supports HART and MODBUS protocols.

The processing of all digital quantities has strong anti-interference ability, reliable measurement, and high precision.

- There are no moving parts or flow-obstructing parts in the pipeline. There is almost no additional pressure loss during measurement, and the requirements for straight pipe sections are low.

- The measurement results have nothing to do with physical parameters such as flow rate distribution, fluid pressure, temperature, density, and viscosity.

- The range can be modified online or on the site according to the actual needs of users.

- High-definition backlit LCD makes reading easier in direct sunlight or in a dark room.

- Fast computing speed, high accuracy, programmable frequency, and low-frequency rectangular wave excitation improve the stability of flow measurement and low power consumption.

- The converter has functions such as self-diagnosis alarm output, empty load detection alarm output, upper and lower flow alarm output, batch control, and other functions.

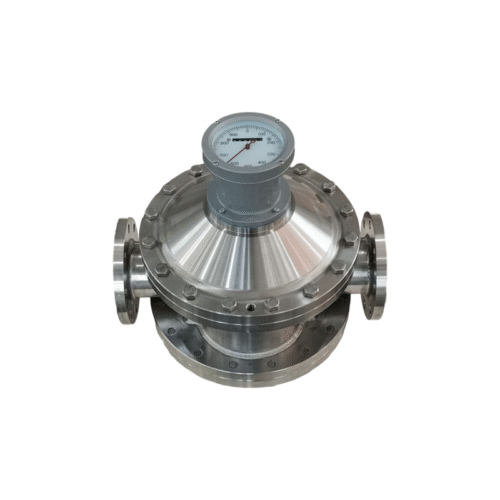

- The high-pressure electromagnetic flowmeter sensor adopts PFA screening lining technology, which is resistant to high pressure and negative pressure. It is specially used in the petroleum, chemical, and other industries.

- There are three totalizers inside, which can be recorded separately: forward total amount, reverse total amount, and difference total amount.

Electromagnetic flow meter can be widely used in petroleum, chemical, iron and steel, food, electric power, paper making, metallurgy, water supply and drainage, petrochemical, medical, environmental protection, and other industries in the conductive liquid flow measurement.

Its value is

Its value is