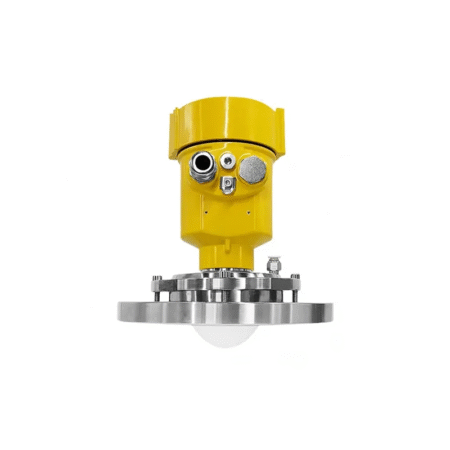

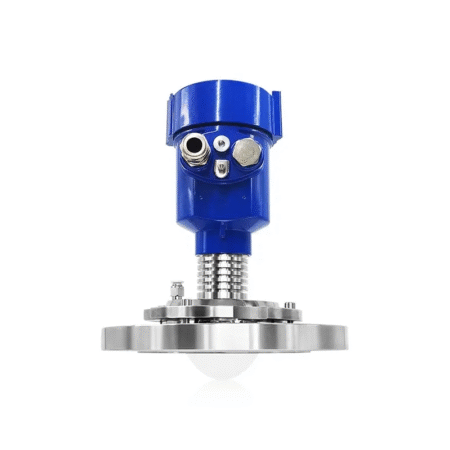

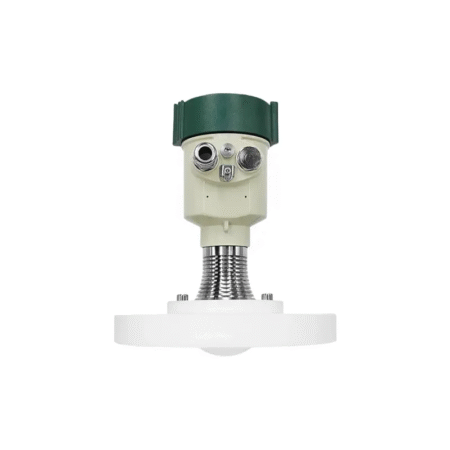

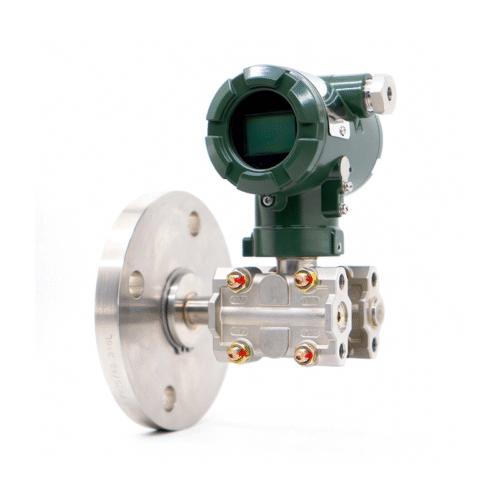

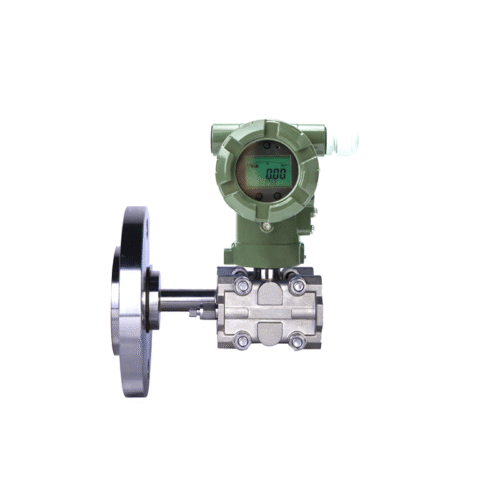

The QYL-R01-S large lens radar level transmitter has various models, which can be customized according to your requirements.

The QYL-R01-S large lens radar level transmitter has various models, which can be customized according to your requirements.

Due to its higher operating frequency and shorter wavelength, it has a better reflected signal on the medium and has unique advantages in measuring low dielectric constant liquids/solids/powders, thereby obtaining better measurement results, even in challenging environments with extreme temperatures, high pressures, or the presence of vapors, dust, or foam.

Principle

The general principle of the FM continuous wave radar level transmitter is that the radar emits electromagnetic waves at the top of the tank. The electromagnetic waves are received by the radar after hitting the medium and being reflected. The frequency difference δf between the received signal and the transmitted signal is proportional to the distance R from the surface of the medium: R=C(speed)*δf(frequency difference)/2/K(frequency modulation slope). Since the speed of light C and the frequency modulation slope K are known, the frequency difference δf can be used to estimate the distance R from the radar installation point to the material surface. The material level height is then obtained by subtracting this spatial distance from the known total height of the tank (referred to as the empty height).

As a 78-80GHz band radar used in the industrial measurement field, high-precision, non-contact level and liquid level measurement has incomparable advantages over other ordinary microwave pulse radars and guided wave radars. It has an extremely narrow beam and penetration capabilities, and can adapt to ultra-complex working conditions without weakening measurement performance.

- Huge range reaches 120 meters;

- Provide a very narrow beam angle, allowing for precise targeting and measurement, even in small or obstructed tanks.

- Offers millimeter-level accuracy, making it ideal for applications where precise level control is critical.

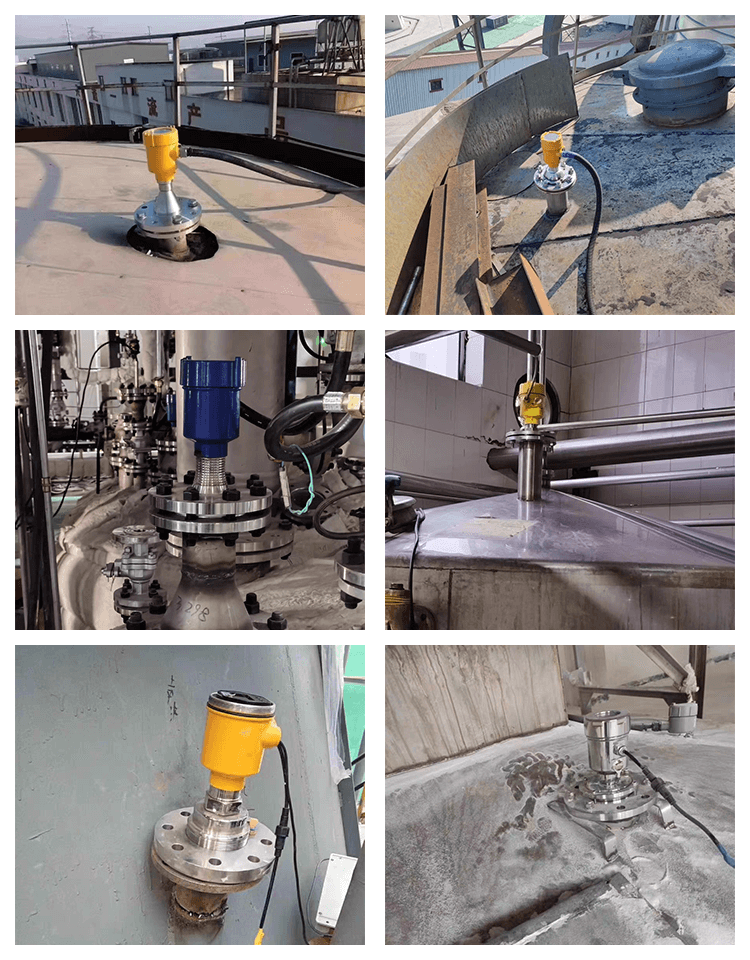

- It is designed to withstand harsh industrial conditions, including extreme temperatures, high pressures, and aggressive environments.

- The compact design and simple installation process make it easy to integrate into existing systems. Additionally, its non-contact nature reduces the need for frequent maintenance.

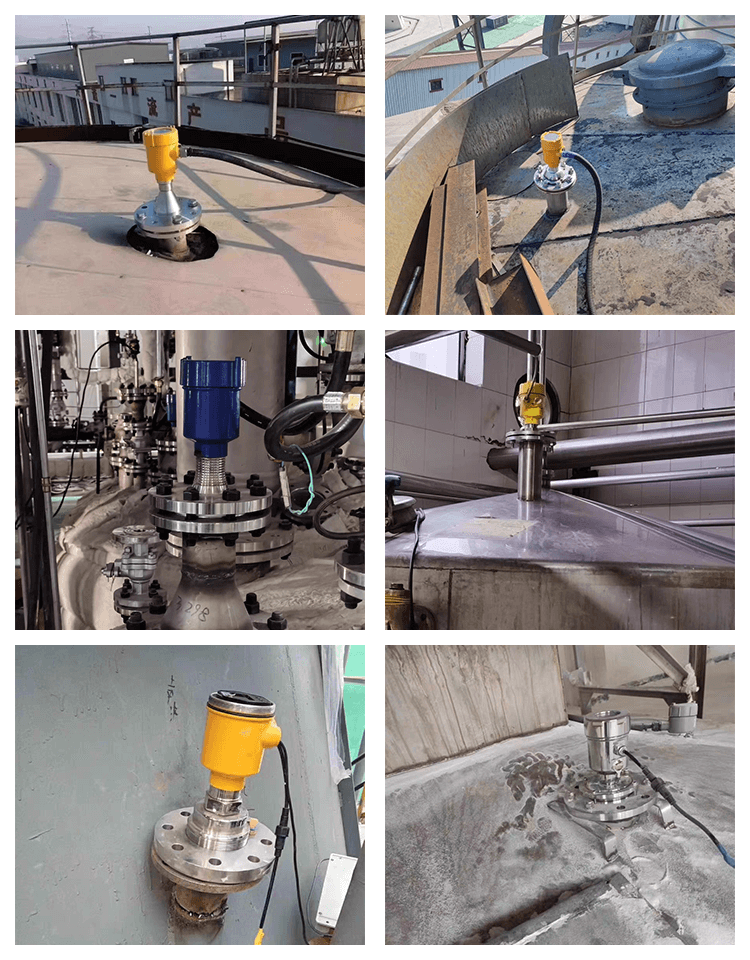

The 80G radar level meter is widely used in various industries for accurate and reliable level measurement. Its non-contact measurement capability, high precision, and stable performance make it suitable for many challenging environments.

1. The electromagnetic wave emission angle is less than 3°, suitable for measurement in narrow spaces or guided wave pipes;

2. 120m measurement range, suitable for measurement of extremely large storage tanks;

3. The measurement blind area is in the range of 7-8cm, suitable for the measurement of small storage tanks.

4. Very high measurement accuracy, suitable for high-precision metrology level measurement;

5. It has rich echo processing algorithms and empirical data on various working conditions and environments; it has unique advantages that other similar products do not have for extremely harsh working conditions, such as strong dust and steam, or storage tanks with special processes, such as stirring and heating rods.

The QYL-R01-S large lens radar level transmitter has various models, which can be customized according to your requirements.

The QYL-R01-S large lens radar level transmitter has various models, which can be customized according to your requirements.